EB Contract Welding

Offering the Widest Range of EB Welding Services

Sciaky’s welding job shop offers a wide range of affordable EB welding services for customers in a wide variety of industries all over the world.

EB Job Shop Welding Services

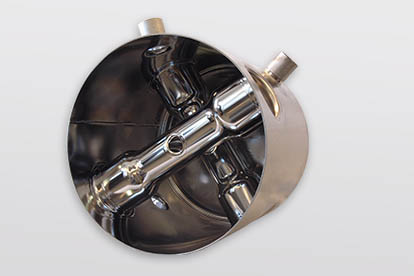

We have the capability to weld large assemblies up to 24 feet in length and 92 inches in diameter, as well as tiny parts that fit in the palm of your hand. Whether your requirements call for the development of a prototype part or fabrication services for large volume production, Sciaky and Production Engineering have the right solution to meet your needs. Best of all, Sciaky's custom EB welding services are competitively priced and offer tremendous advantages over smaller job shops in terms of equipment and expertise. You won’t find a more complete EB welding job shop anywhere in the world.

Sciaky’s process development laboratory is staffed with highly qualified personnel and the latest equipment to evaluate your specialized welding applications and feasibility programs. Our skilled technicians offer the latest welding processes, system design, weld joint design, metallurgical expertise, and programming skills. The process laboratory occupies about 4,000 square feet within the service facility. Additional testing, such as radiographic inspection and ultrasonic inspection is available as well.

EB Welding Job Shop Services

Electron Beam Welding Consultation: Have a Production Engineering EB welding expert show you how to get the most out of your Sciaky EB welding system

Welding Specification Certifications

- Standards such as AMS2680, AMS2681B, AWSD17.1, AWSC7-3, Mil-W-46132, ASME Boiler & Pressure Vessel Code

- Quality Procedures and Manuals, detailed operation sheets, Approved EB weld schedules with configuration controls

- Nadcap accreditation for EB welding and Quality Systems AS7003 and AC7004

Customer-Specific Certifications

- Custom Part Fixturing and High Throughput Fixturing

- Work Handling Capacity up to 20 tons

- Cleaning and Painting Facilities

- Heat Treatment | Stress Relief

- Metallurgical Analysis

- NDI—Leak checking, Die Penetrant inspection, Laboratory Testing and Demonstration Capabilities

- Pre- or Post-Weld Machining

- Assembly and Finish Machining