Rocker Arm

Rocker Arm Welders

The rocker arm type welder is a commonly used stationary spot welder for low production applications. It is actuated by a mechanical foot pedal or by an air cylinder. The lower arm is usually adjustable up and down for set up, but is stationary during the weld. The upper arm is not adjustable, but pivots or “rocks” into the weld position, to form the weld circuit.

Rocker arm machines are well suited for a wide range of work, up to a welding capacity of 2 thicknesses of 1/8” thick steel. Foot operated machines are best suited for miscellaneous job shop work, including many sheet metal fabrications. Air-operated machines are best suited for production runs, particularly where the runs are not too long and minimal set up tooling is required.

Our single phase AC air operated rocker arm spot welders are available with standard throat depths from 12” to 36”. A fabricated steel frame supports the heavily reinforced rocker arm assembly that is actuated by a double acting air cylinder. A stacked core transformer has water cooled secondaries supporting the duty cycle experienced in higher production applications. Variable heat range selection is possible with an adjustable side mounted tap switch, when specified.

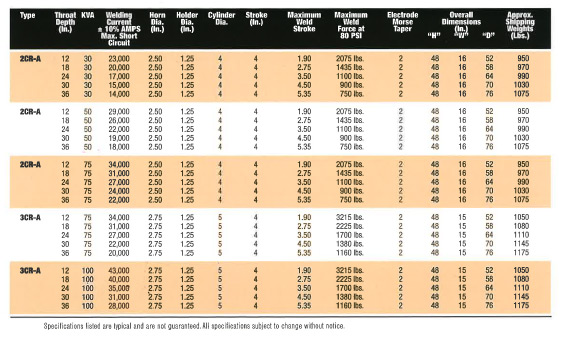

Rocker arm welders adapt well to various production requirements that may occur over the long life of this equipment. A cast alloy knee on the lower arm is vertically adjustable to handle different application in the future. Each basic welder comes in differ sizes as shown in the table below. The 2CR has a 2 2/4” diameter copper arm (horn), and the 3CR has a 2 3/4” diameter copper arm (horn). Typically, we supply a 1¼” diameter ejector type electrode holder for 5RW water cooled electrodes with each arm. A water circuit is provided throughout the welder.

Entron controls are well suited for all rocker arm welders. We provide the appropriately sized control and transformer needed for each application. Any other standard weld control brand (WTC, Medar, Unitrol, etc.) can be easily mounted on the rocker arm welder to meet your specific plant weld control specifications.

Each welder comes complete with all necessary air line components, including: valves, filter, lubricator, pressure gauge, and adjustable flow control regulator. A shrouded foot switch is also supplied.