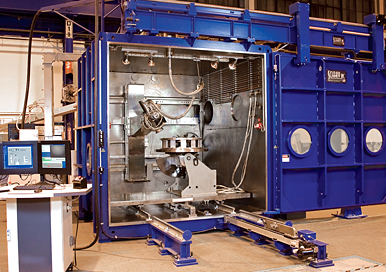

Large Chamber

Overview of Large-Chamber Welding Systems

Sciaky Inc. specializes in large vacuum chamber electron beam welding systems with state-of-the-art internal moving guns. These machines commonly utilize low voltage and high power, and are ideally suited for large-scale parts.

Advantages of large-scale EB welding machines include:

- Motion system designs include ceiling mounted gantries and rear-wall mounted booms that, depending upon system configuration, manipulate the EB gun using X, Y, Z, and gun tilt.

- Standard designs are available, and custom engineered solutions are often created to meet customer requirements.

- CNC control systems coordinate all EB process parameters.

- High depth-to-width ratio weld profiles provide low distortion and excellent mechanical properties.

- The high vacuum environment provides an excellent inert environment for welding many reactive metals and alloys with pumping technologies up to 200,000 l/s.

- High precision and repeatability.

- Sciaky offers many standard CNC-controlled part manipulators, designed in several load capacities, including rotary tables, rotary headstock / tailstocks, and rotary tilt positioners.

- Scalability of process to weld thin foils to thick sections (greater than 2.5" depth-of penetration).

Sciaky's Large-Chamber EB welding systems are available in a variety of configurations. Click on an system below to learn more about each machine's capabilities.